- 2019-06-22

Brief analysis of the advantages and disadvantages of brightener OB

Brightener OB is a general-purpose brightener used mainly for the whitening of plastic products and paint inks.

- 2022-07-15

TPU de-yellowing transparent agent

TPU de-yellowing transparent agent has the advantages of anti-aging, good dispersibility, good stability, etc.After use, the product remains clear and transparent for a long time and has no blue light, and does not turn yellow in the later stage.

- 2022-07-14

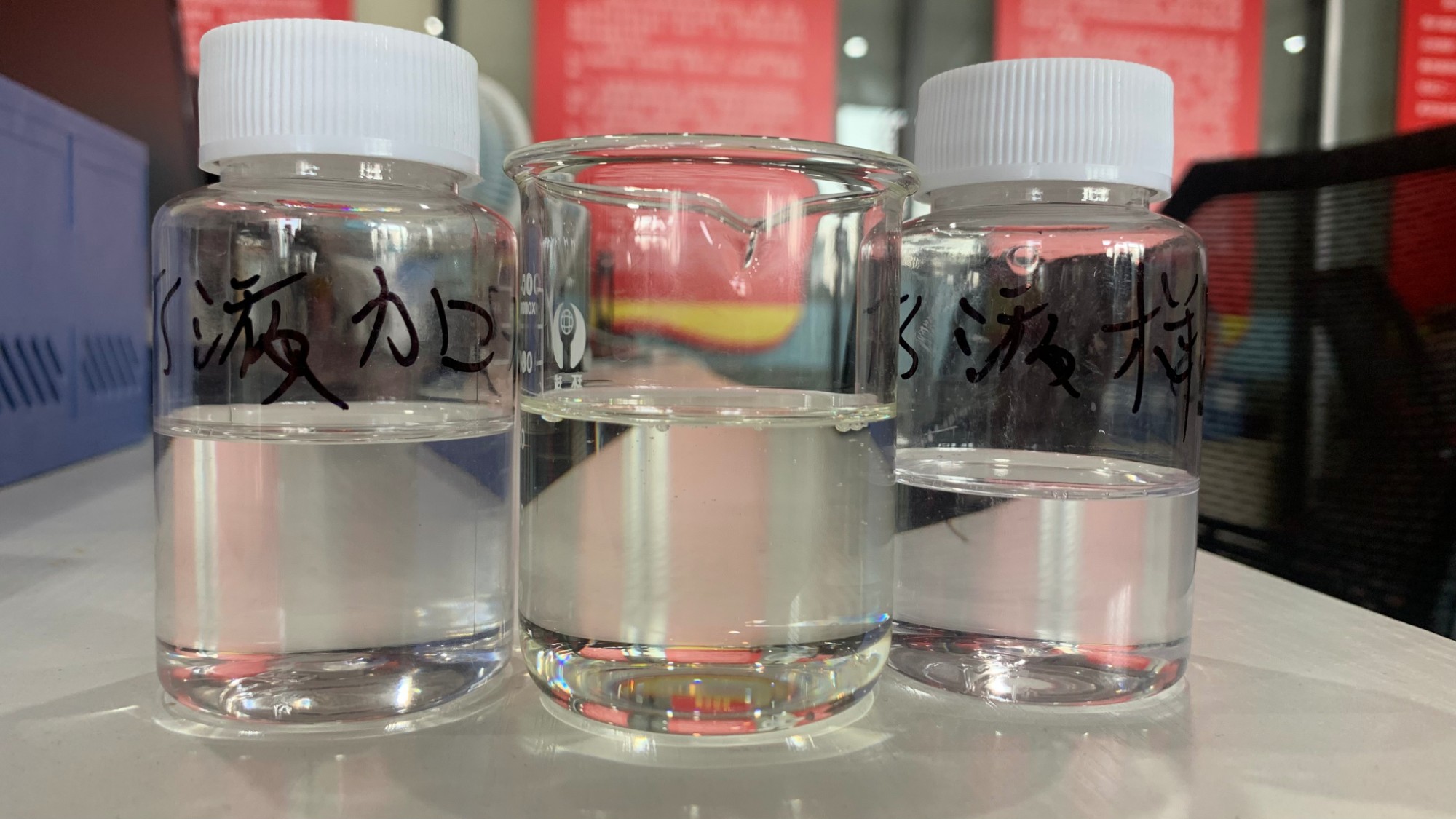

Acrylic de-yellowing transparent agent

Acrylic de-yellowing transparent agent has the advantages of good dispersibility, good weather resistance, good stability, etc.,which is a blue liquid in appearance, only needs to add 10-30 grams per ton of raw materials, with small dosage and low co...

- 2022-07-14

RQT-SP-3 PP toughening agent

SP-3 PP toughening agent is a product specially designed to solve the problem of brittleness and cracking of PP products. It is different from the traditional toughening agent. While increasing toughness, the product will not deform, with less dosage...

- 2022-07-13

RQT-SP-3 toughening agent

Different from the traditional toughening agent, its cost is lower, which is a quarter of the cost of POE, which is safer and more environmentally friendly. , The toughening effect is better, RQT-SP-3 toughening agent is widely used in amorphous plas...

- 2022-07-13

Chlorinated paraffin wax de-yellowing transparent agent

A de-yellowing and penetrating agent that prolongs the yellowing time of ultraviolet rays. Different from the traditional de-yellowing transparent agent, it has the advantages of good dispersibility, small migration, light resistance, high temperatur...

- 2022-07-12

RQT-X-3 UV absorber for paint and ink

It can strongly absorb ultraviolet rays (especially the wavelength of 290-400nm), so it is different from traditional UV absorbers.And its weather resistance grade can reach 8.

- 2019-10-16

Application of Fluorescent Brightener OB

Fluorescent brightener OB, its appearance is light yellow powder, melting point is 201 ° C to 202 ° C, which means it can be used for thermoplastic plastic, polyvinyl chloride, polystyrene, polyethylene, polypropylene, ABS ,acetate fiber.